Functionality Create a stock removal actionfeature of the K inventory software enables you to efficiently manage your company’s material issues.

This feature enables you to check out references and files, move references and assign them to a user or group of users.

1. In the left-hand menu, click on the icon Interventions ![]()

2. Click on Create an intervention ![]()

3. In the Description field of the Stock actionsection, click on the

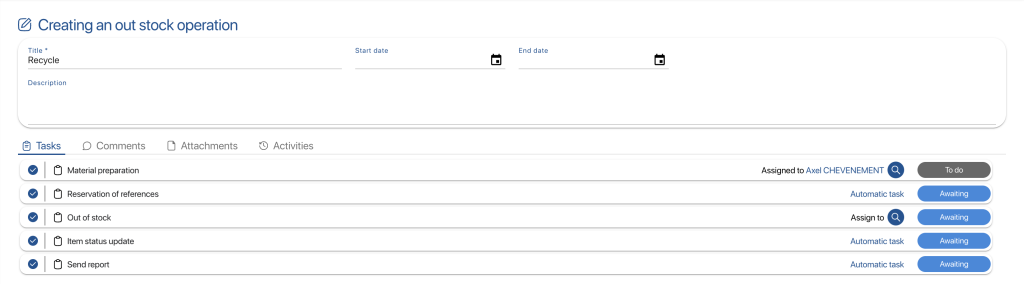

4. Complete the information on the Creating an exit intervention :

- Title

- Start date

- End date

Creating an output intervention

Creating an output intervention

5 (Optional) To remove a non-mandatory step, uncheck its check box.

For example, uncheck the following tasks Material preparation and Reserving references

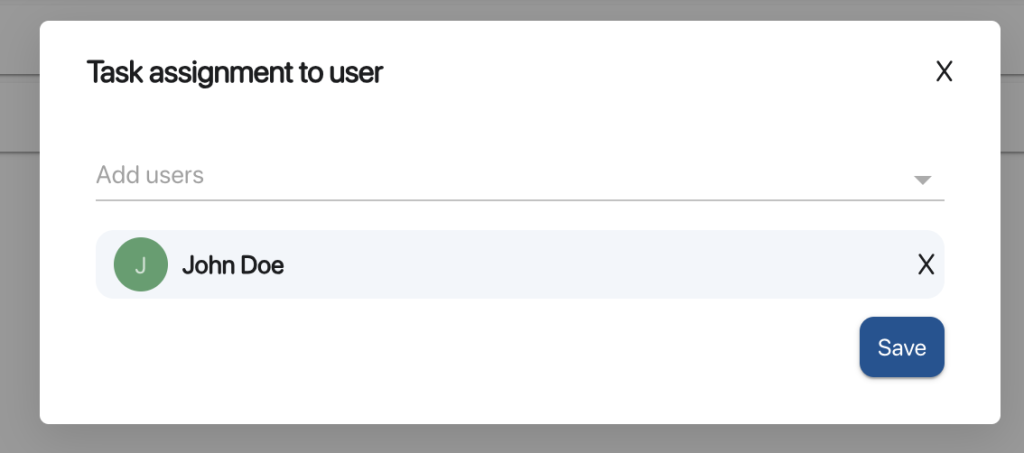

6. To assign a task to a user or group of users, click on Assign tothen click on the

7. Save your changes with the Save

Selecting the account assigned to the task

Selecting the account assigned to the task

8. At the bottom right of the screen, save your changes using the Save

9. To select the references to be moved, click on the ![]() icon and then on the

icon and then on the ![]() button, or click on the job name.

button, or click on the job name. ![]()

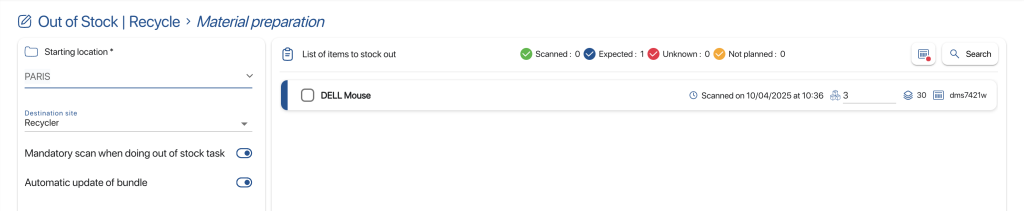

10. In Start locationselect the folder where the references and files to be removed from stock are located.

11. In Recipientselect the service, account or department to which the references and files are to be sent.

Perimeter and recipient selection

Perimeter and recipient selection

12. Go to List of references and files to be removed click on the ![]() icon to scan the references to be added to the intervention.

icon to scan the references to be added to the intervention.

13. In the list of output references, click on the ![]() icon to perform a manual search.

icon to perform a manual search.

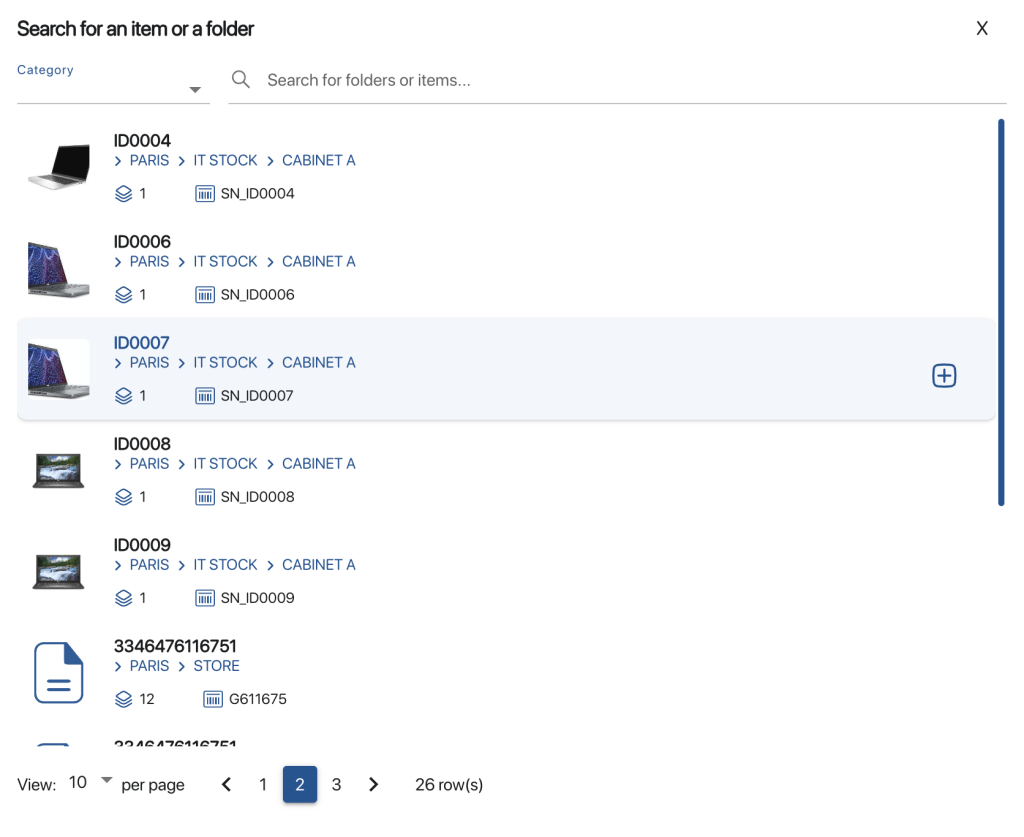

14. In the Find a reference pop-up, select a category to perform an initial filter on the search for a reference or folder.

![]() Reference selection

Reference selection

15. In the list of references displayed, click on the ![]() icon of the reference you wish to add.

icon of the reference you wish to add.

Selection of references

Selection of references

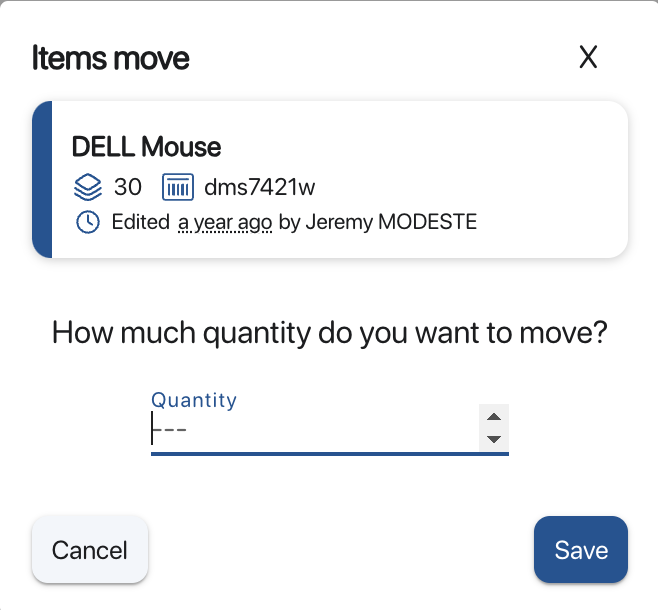

16. In the Quantity field, enter the number of products to be moved.

Reference search pop-up

Reference search pop-up

17. Save the quantity entered using the Save

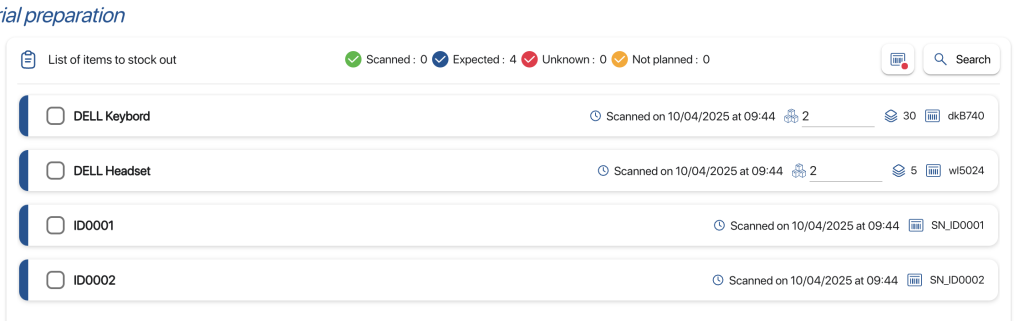

18. In List of references to be removedclick on the ![]() icon to scan the references to be added to the intervention.

icon to scan the references to be added to the intervention.

List of references and files to be released

List of references and files to be released

19. To remove a reference or folder from the list of references to be removed, click on the ![]() icon on the line concerned, then on the

icon on the line concerned, then on the ![]()

20. Save your changes with the Save

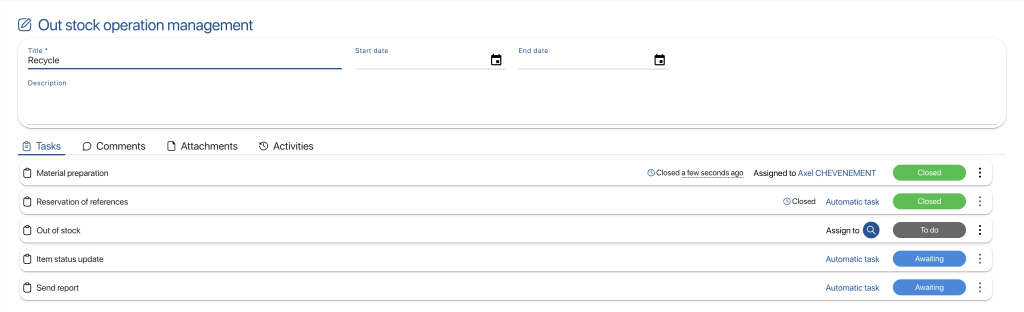

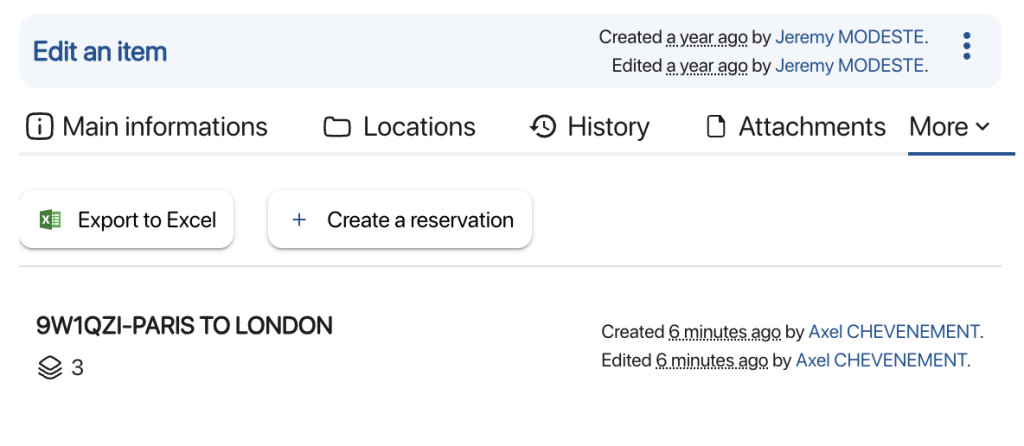

Result of exit intervention creation

Result of exit intervention creation

To continue browsing, here are a few articles related to this page:

Product – Creating a new reservation

Product – Creating a new reservation